We’ve been hearing a lot about plant-based substitutes for red meat and poultry, milk and other every-day foods for a few years, now. But fish and seafood have been largely absent from the conversation. Now, researchers have 3D-printed convincing seafood mimics…

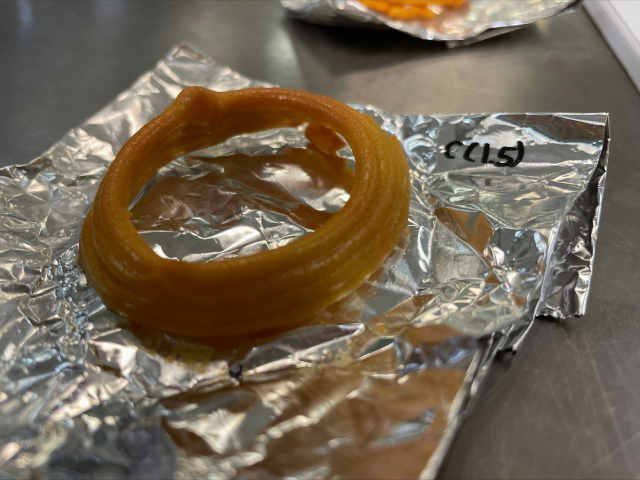

A prototype 3D-printed calamari ring.

A prototype 3D-printed calamari ring.

The Mediterranean Diet and other healthy eating regimes emphasize the importance of incorporating seafood in our diets. But fish and other seafoods are among the most expensive protein foods we can buy. Especially if we live far from the water.

And seafoods have been the most challenging food type for plant-based meat substitute developers to crack.

But now researchers have taken a brave leap of imagination and discovered a way to 3D print fish and seafoods using a substrate made from algae and mung bean protein.

The challenge

“Plant-based seafood mimics are out there, but the ingredients don’t usually include protein. We wanted to make protein-based products that are nutritionally equivalent to or better than real seafood, and address food sustainability,” says Dr. Dejian Huang, principal investigator on the study.

The most daunting challenges that have faced fish-mimic makers include texture, mouth feel and the mild, delicate flavours of seafood.

What they did

To reach their goal, the team combined mung bean protein, a microalgae extract and plant-based oils containing omega-3 fatty acids to produce a 3D printing ‘ink’. Microalgae already have a ‘fishy’ flavour and lend themselves naturally to incorporation in seafood mimics.

Depositing the edible ink layer by layer created different textures, some fatty and smooth and others fibrous and chewy, in a single product.

“We printed salmon filets with protein from red lentils because of the protein’s color, and we’ve printed shrimp,” says Huang. “Now, we wanted to print something else interesting with the potential for commercialization – calamari rings.”

The takeaway

Huang has no illusions about the consumer uptake of his team’s new plant-based seafood mimics. He says it’s reasonable to expect 3D-printes seafood products to be available in fine-dining restaurants or specialty outlets in a few years.

“I think people will like our plant-based mimic. From a novelty perspective, it has that seafood taste but comes from only sustainable plant-based sources,” concludes grad student Poornima Vijayan.

But the researchers admit other significant challenges still confront the mass manufacture and marketing of such plant-based foods. Chief among them, scaling up the process.

Another dimension for future research is the question of food sensitivities. Huang says the team’s 3D-printed products are entirely vegan, and should be safe for those who suffer from fish and seafood allergies. “I don’t think that there are many known cases of allergies to microalgae proteins or mung bean proteins. But we don’t know yet because it’s still a new combination,” he notes.

My take

I agree with Huang and Vijayan that scaling up the manufacturing process is the chief challenge facing any commercial application. 3D printing is a very time-consuming and expensive process as the technology currently stands. I suspect that’s why Huang foresees only a limited, high-end market for his team’s products for at least a few years to come.

On the other hand, the possibility of mass marketing plant-based seafood products might just spur 3D printer makers to pour significant development effort into new generations of their machines.

But I also have to reiterate my previous assertions – in concert with global economists – that plant-based mimics of traditional foods will prove to be only bridging products as the world moves toward a plant-protein-based reality. Like so many other issues we face these days, it’s rooted in the ugly, overarching reality of climate change.

~ Maggie J.